As the world shifts towards sustainable transportation, a crucial question arises: What makes electric vehicles (EVs) efficient and powerful? The answer lies in their electric vehicle motor, a critical component that determines the overall performance of EVs.

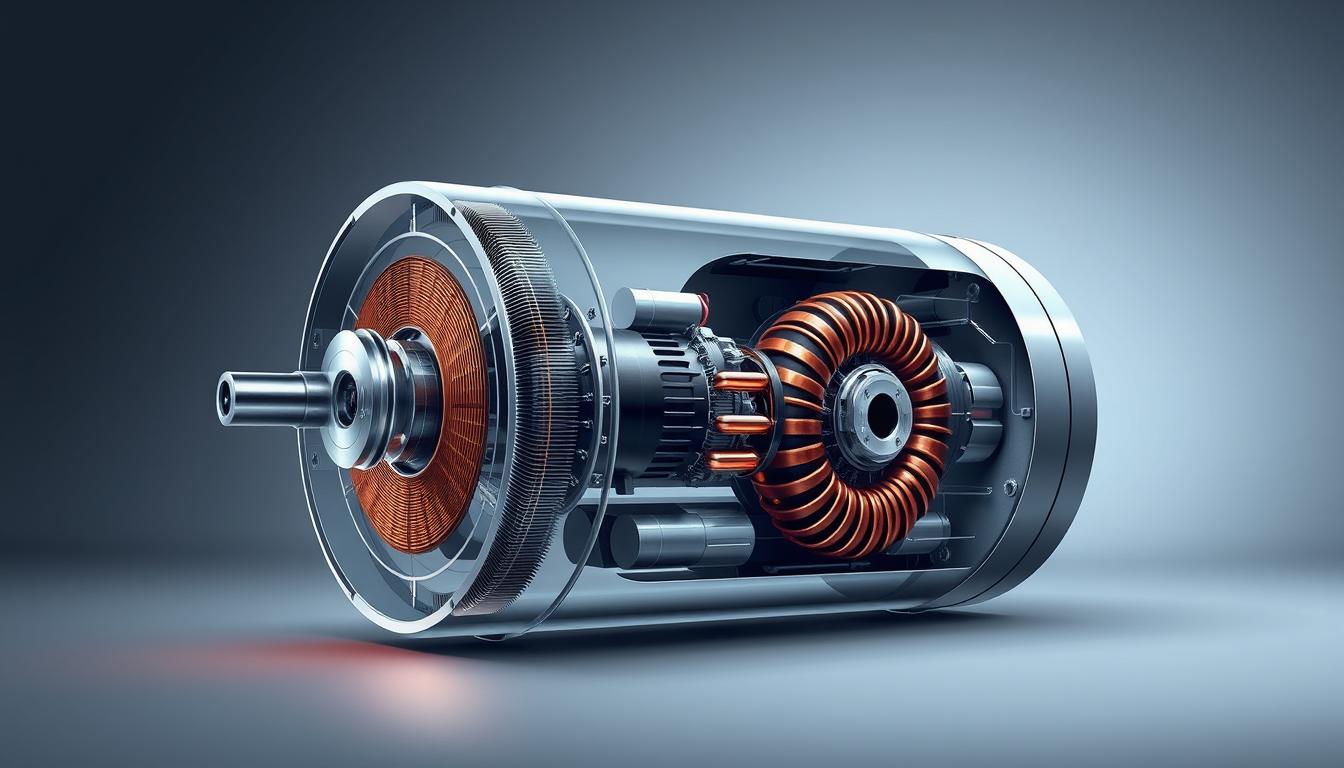

The electric car motor technology has evolved significantly, enabling EVs to achieve remarkable efficiency and range. At the heart of this technology is the electric motor drive, which plays a pivotal role in converting electrical energy into mechanical energy.

This innovation is revolutionizing the automotive industry, making EVs more appealing to a wider audience. As we explore the intricacies of electric motor drives for EVs, we will uncover the secrets behind their efficiency and performance.

Key Takeaways

Table of Contents

- The electric vehicle motor is crucial for the performance and efficiency of EVs.

- Advancements in electric car motor technology have significantly improved EV range and efficiency.

- The electric motor drive is a key component in converting electrical energy into mechanical energy.

- Innovations in electric motor drives are making EVs more appealing to consumers.

- The future of EVs is closely tied to the development of more efficient electric motor drives.

Understanding Electric Motor Drives for EVs

Electric motor drives play a pivotal role in determining the performance, efficiency, and overall driving experience of electric vehicles. As the automotive industry continues to electrify, the importance of understanding these systems cannot be overstated.

What Are Electric Motor Drives?

Electric motor drives are systems that control the electrical energy supplied to an electric motor, converting it into mechanical energy to propel the vehicle. They are essentially the brain behind the operation of an electric vehicle, dictating how much power is delivered and when. The efficiency and reliability of these drives directly impact the vehicle’s overall performance and range.

The Role of Motor Drives in Electric Vehicles

Motor drives in EVs are responsible for managing the flow of electrical energy to the motor, ensuring optimal performance under various driving conditions. They enable features like regenerative braking, where the motor acts as a generator to recharge the battery during deceleration. This not only enhances efficiency but also improves the driving experience by providing smooth acceleration and braking.

Key Components of EV Motor Drive Systems

The key components of EV motor drive systems include the motor itself, power electronics (such as inverters and converters), and control systems. The electric vehicle motor controller is a critical component that regulates the motor’s operation, ensuring it runs efficiently and effectively. The integration of these components determines the overall efficiency, reliability, and performance of the electric vehicle.

Understanding the intricacies of ev motor drive technology and electric car motor drive systems is essential for advancing the field and improving the viability of electric vehicles as a sustainable transportation solution.

Types of Electric Motor Drives Used in Modern EVs

Modern electric vehicles (EVs) utilize a variety of electric motor drives, each with its unique characteristics and advantages. The choice of motor drive significantly impacts the vehicle’s performance, efficiency, and overall cost.

The diversity in electric motor drives allows manufacturers to tailor their vehicles to specific needs, whether it’s for high-performance, long-range, or cost-effective solutions. Understanding the different types of motor drives is crucial for appreciating the advancements in EV technology.

Permanent Magnet Synchronous Motors (PMSM)

Permanent Magnet Synchronous Motors are widely used in EVs due to their high efficiency and power density. PMSMs utilize permanent magnets in the rotor, which eliminates the need for excitation current, thus reducing losses.

These motors are known for their smooth operation and high torque-to-weight ratio, making them ideal for applications where space and weight are critical factors.

Induction Motors

Induction Motors, also known as asynchronous motors, are another popular choice for EVs. They are known for their robustness and reliability, with a simple construction that reduces manufacturing costs.

Induction Motors operate by inducing a current in the rotor, which interacts with the stator’s magnetic field to produce torque. While they may not be as efficient as PMSMs at all operating points, they offer great durability and are widely used in various EV models.

Switched Reluctance Motors

Switched Reluctance Motors (SRMs) are gaining attention for their simplicity and ruggedness. They operate by switching the current to the windings in synchronization with the rotor position, creating reluctance torque.

SRMs are known for their potential in high-speed applications and their ability to operate efficiently over a wide speed range. However, they can be noisy and require sophisticated control algorithms.

Axial Flux Motors

Axial Flux Motors represent a newer technology that offers high power density and efficiency. They have a unique configuration where the magnetic flux flows axially, allowing for more compact designs.

Axial Flux Motors are particularly promising for high-performance EVs, where their compactness and high torque output can be fully leveraged.

| Motor Type | Efficiency | Power Density | Cost |

|---|---|---|---|

| Permanent Magnet Synchronous Motors | High | High | Medium |

| Induction Motors | Medium to High | Medium | Low to Medium |

| Switched Reluctance Motors | High | Medium | Low |

| Axial Flux Motors | High | Very High | High |

The table above summarizes the key characteristics of the different motor types used in EVs, highlighting their efficiency, power density, and relative costs. This comparison is crucial for understanding the trade-offs involved in selecting a motor drive for a particular EV application.

How to Choose the Right Electric Motor Drive for EVs

Choosing the correct electric motor drive is essential for optimizing the performance, range, and reliability of electric vehicles (EVs). The electric motor drive is a critical component of an EV’s powertrain, directly influencing its efficiency, power output, and overall driving experience.

Assessing Vehicle Performance Requirements

When selecting an electric motor drive, the first step is to assess the vehicle’s performance requirements. This includes considering factors such as the desired top speed, acceleration, and torque. For instance, high-performance EVs may require motor drives capable of delivering high torque and power.

To evaluate these requirements, manufacturers can refer to the following table, which outlines typical performance characteristics for different types of EVs:

| EV Type | Top Speed (mph) | 0-60 mph (seconds) | Torque (Nm) |

|---|---|---|---|

| City Car | 90 | 10 | 150 |

| Sports Car | 150 | 3 | 400 |

| Family Sedan | 120 | 7 | 250 |

Evaluating Efficiency and Range Impact

The efficiency of the electric motor drive directly impacts the vehicle’s range. High-efficiency motor drives can significantly reduce energy consumption, thereby extending the vehicle’s range. It’s crucial to evaluate the motor drive’s efficiency under various operating conditions.

Considering Size and Weight Limitations

The size and weight of the electric motor drive are also critical factors. The motor drive must fit within the vehicle’s design constraints while minimizing weight to optimize overall vehicle efficiency.

Analyzing Cost-Effectiveness

Finally, the cost-effectiveness of the electric motor drive is a significant consideration. Manufacturers must balance the cost of the motor drive with its performance and efficiency benefits. A comprehensive analysis of the total cost of ownership, including energy savings and maintenance costs, can help determine the most cost-effective solution.

Implementing Electric Vehicle Motor Controllers

Electric vehicle motor controllers play a pivotal role in optimizing the performance and range of EVs. The effectiveness of these controllers depends on several critical components and configurations.

Setting Up Power Electronics Systems

The power electronics system is the backbone of any EV motor controller. It involves the integration of power devices such as IGBTs (Insulated Gate Bipolar Transistors) or MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) that handle high voltages and currents. Efficient power electronics design is crucial for minimizing losses and maximizing the overall efficiency of the EV.

Configuring Inverter Parameters

The inverter is a key component of the EV motor controller, responsible for converting DC power from the battery to AC power for the motor. Configuring inverter parameters such as switching frequency, dead time, and modulation index is essential for achieving optimal performance. Proper configuration can significantly enhance the efficiency and reliability of the motor drive system.

Programming Control Algorithms

Control algorithms dictate how the motor controller responds to various inputs and operating conditions. Advanced control algorithms can optimize the performance of the EV by adjusting parameters in real-time. Field-Oriented Control (FOC) and Model Predictive Control (MPC) are examples of sophisticated algorithms used in modern EV motor controllers.

Establishing Thermal Management Solutions

Effective thermal management is critical for maintaining the reliability and longevity of EV motor controllers. This involves designing cooling systems that can efficiently dissipate heat generated by the power electronics and motor. Thermal modeling and simulation are essential tools for developing optimal thermal management solutions.

| Component | Function | Importance in EV Motor Controller |

|---|---|---|

| Power Electronics | Handles high voltage and current | High |

| Inverter | Converts DC to AC power | High |

| Control Algorithms | Optimizes motor performance | High |

| Thermal Management | Dissipates heat | High |

Optimizing Electric Vehicle Powertrain Solutions

As electric vehicles continue to gain popularity, optimizing their powertrain solutions becomes increasingly important. The powertrain is a critical component of an electric vehicle, responsible for converting electrical energy into mechanical energy to propel the vehicle. Optimizing this system can significantly enhance the overall efficiency, performance, and range of EVs.

Integrating with Battery Management Systems

One crucial aspect of optimizing electric vehicle powertrain solutions is integrating with battery management systems (BMS). The BMS plays a vital role in monitoring and controlling the state of charge, voltage, and temperature of the battery cells. By integrating the powertrain with the BMS, manufacturers can ensure that the vehicle operates within safe limits, thereby enhancing safety and efficiency.

Key benefits of BMS integration include:

- Improved safety through precise monitoring and control

- Enhanced efficiency by optimizing charge and discharge cycles

- Increased battery lifespan through balanced cell management

Configuring Regenerative Braking

Regenerative braking is another critical component of electric vehicle powertrain optimization. This feature allows the vehicle to capture kinetic energy during braking and convert it back into electrical energy, which is then stored in the battery. Configuring regenerative braking systems effectively can significantly improve the vehicle’s overall efficiency and range.

Factors to consider when configuring regenerative braking include:

- The driver’s braking behavior and preferences

- The vehicle’s speed and deceleration rates

- The battery’s state of charge and capacity to absorb regenerative energy

Calibrating Torque and Power Distribution

Calibrating torque and power distribution is essential for optimizing the performance of electric vehicles. This involves adjusting the motor’s output to match the vehicle’s operational requirements, such as acceleration, cruising, and braking. Proper calibration ensures that the vehicle delivers the desired performance while maintaining efficiency.

Fine-Tuning Software Parameters

Fine-tuning software parameters is a critical step in optimizing electric vehicle powertrain solutions. This involves adjusting various software settings to optimize the performance, efficiency, and responsiveness of the vehicle. By fine-tuning parameters such as throttle response, regenerative braking levels, and energy management strategies, manufacturers can tailor the vehicle’s behavior to meet specific driving conditions and user preferences.

Some key software parameters to fine-tune include:

| Parameter | Description | Impact on Vehicle Performance |

|---|---|---|

| Throttle Response | Adjusts the sensitivity of the accelerator pedal | Affects acceleration and responsiveness |

| Regenerative Braking Levels | Controls the amount of energy recovered during braking | Influences efficiency and braking feel |

| Energy Management Strategies | Optimizes energy distribution between the battery and motor | Impacts overall efficiency and range |

Troubleshooting and Maintaining EV Drive Systems

Effective troubleshooting and maintenance are crucial for the longevity and performance of electric motor drive for EVs. As the heart of an electric vehicle’s powertrain, the drive system requires regular checks to ensure optimal operation.

Diagnosing Common Motor Drive Issues

Common issues with EV drive systems include overheating, vibration, and noise. Diagnosing these problems involves checking the motor controller, inspecting wiring, and analyzing performance data. For instance, an electric vehicle motor controller malfunction can lead to reduced system efficiency.

Resolving Power Electronics Failures

Power electronics failures in EV drive systems can be critical. Resolving these issues often involves replacing faulty components, such as IGBTs or capacitors, and updating the ev motor drive technology to the latest standards.

Performing Preventive Maintenance

Preventive maintenance is key to minimizing downtime. This includes regular software updates, inspection of electrical connections, and cooling system checks. By staying proactive, EV owners can avoid costly repairs.

Updating Control Software and Firmware

Updating the control software and firmware of an EV’s drive system can significantly enhance performance and efficiency. Manufacturers often release updates that improve the overall ev motor drive technology, making it essential to keep the system current.

By following these guidelines, EV owners and technicians can ensure that electric vehicle drive systems operate at their best, providing reliable and efficient performance.

Conclusion: The Future of Electric Propulsion Technology

The future of electric propulsion for vehicles is rapidly evolving, driven by advancements in electric motor technology for electric vehicles. As the industry continues to grow, electric vehicle powertrain solutions are becoming increasingly sophisticated, enabling more efficient and powerful vehicles.

Key developments in motor drive systems, such as improved power electronics and advanced control algorithms, are enhancing the performance and range of electric vehicles. As manufacturers continue to innovate and optimize their designs, we can expect to see even more efficient and capable electric vehicles on the road.

The trend towards more sustainable and environmentally friendly transportation is driving the adoption of electric propulsion technology. With ongoing investments in research and development, the future of electric vehicles looks bright, with potential breakthroughs in areas like advanced battery technologies and more efficient motor designs.

As the industry continues to evolve, it is clear that electric motor drives will play a critical role in shaping the future of electric propulsion for vehicles. By staying at the forefront of these developments, manufacturers and consumers alike can benefit from the advancements being made in electric vehicle powertrain solutions.