Are you curious about what powers the future of transportation? As the world shifts towards more sustainable options, understanding ev motor technologies is becoming increasingly important.

Electric propulsion technologies are at the heart of this revolution, enabling vehicles to run efficiently and effectively. But what makes these motors tick, and how do they vary across different models?

This guide will walk you through the basics of electric motor types and their key components, setting the stage for a deeper dive into the world of electric vehicles.

Key Takeaways

Table of Contents

- Understanding the fundamental principles of electric motors.

- Exploring the various types of motors used in electric vehicles.

- Evaluating the performance of different EV motors.

- Discovering the key components that make EV motors efficient.

- Learning about the future trends in ev motor technologies.

Understanding Electric Vehicle Motor Basics

At the core of every electric vehicle is an electric motor, a crucial component that enables the vehicle to move. Electric vehicle motors are designed to convert electrical energy into mechanical energy, propelling the vehicle forward. This process involves several key components working in harmony.

How Electric Motors Convert Energy to Motion

Electric motors in EVs operate on the principle of electromagnetic induction. When an electric current flows through the motor’s windings, it generates a magnetic field that interacts with the motor’s magnetic components, producing torque. This torque is what ultimately drives the vehicle’s wheels. The efficiency of this conversion process is crucial for the overall performance of the EV.

Key factors influencing this efficiency include the design of the motor, the quality of the materials used, and the motor’s cooling system. For instance, some EVs utilize regenerative braking to capture kinetic energy and convert it back into electrical energy, thereby enhancing overall efficiency.

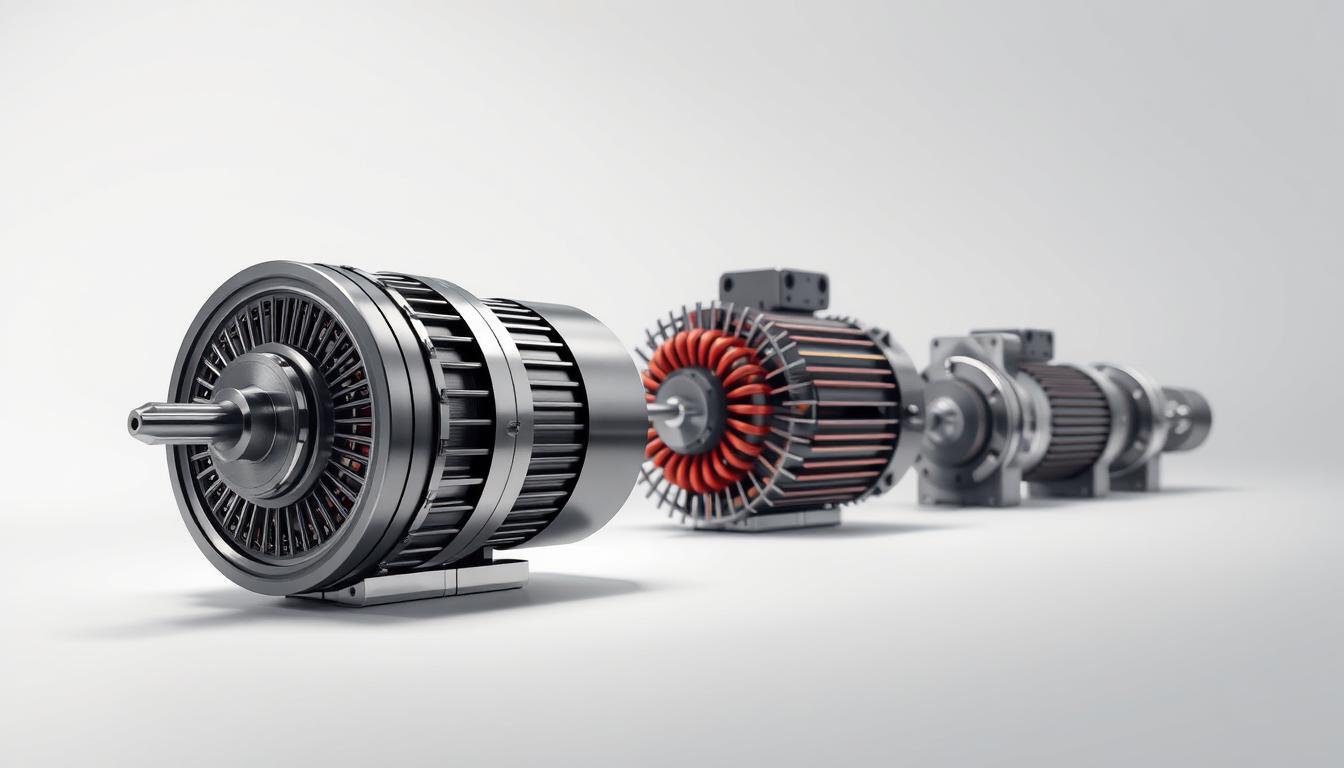

Key Components and Their Functions

The main components of an EV motor include the stator, rotor, and bearings. The stator is the stationary part of the motor that produces a magnetic field, while the rotor is the moving part that is driven by this field. High-quality bearings are essential for reducing friction and ensuring smooth operation. Together, these components work to optimize the motor’s performance and efficiency.

How to Identify Different Motor Systems in EVs

Different EV models may employ various types of electric motors, including DC motors, AC motors, and more advanced designs like axial flux motors. Identifying the type of motor used in an EV can provide insights into its performance capabilities and efficiency. For example, some EVs may use a single motor, while others may employ multiple motors for improved performance and all-wheel drive capability.

- DC motors are known for their simplicity and reliability.

- AC motors offer high efficiency and performance.

- Axial flux motors provide a compact design with high power density.

Types of Electric Vehicle Motors

Electric vehicle motors come in several types, each designed to optimize performance, efficiency, and reliability. The choice of motor significantly impacts the overall driving experience, range, and cost of the vehicle.

DC Motors in Electric Vehicles

DC motors have been widely used in early electric vehicles due to their simplicity and ease of control. They are categorized mainly into brushed and brushless DC motors.

Brushed DC Motors: Operation and Applications

Brushed DC motors operate using a simple design where the rotor (armature) is connected to a commutator and brushes. While they are cost-effective and straightforward to control, their efficiency is limited by brush wear and energy loss. They are less common in modern EVs due to these limitations.

Brushless DC Motors: Benefits and Use Cases

Brushless DC motors (BLDC) eliminate the brushes, reducing maintenance and increasing efficiency. They use electronic commutation to switch the current, providing higher reliability and longer lifespan. BLDC motors are favored in many EV applications for their high power density and efficiency.

AC Motors for EVs

AC motors are another category used in electric vehicles, known for their high efficiency and reliability. They are broadly classified into induction motors and permanent magnet synchronous motors.

Induction Motors: How Tesla Pioneered Their Use

Tesla has been a pioneer in using induction motors in their electric vehicles. These motors work on the principle of electromagnetic induction, where the rotor is induced with a current by the stator’s magnetic field. Tesla’s use of induction motors has shown their potential for high performance and efficiency in EVs.

Permanent Magnet Synchronous Motors: Efficiency Leaders

Permanent Magnet Synchronous Motors (PMSM) use permanent magnets on the rotor, providing high efficiency and power density. They are synchronous because the rotor rotates at the same frequency as the stator’s magnetic field. PMSMs are known for their high efficiency and compact design, making them suitable for many EV applications.

Axial Flux Motors: The Compact Powerhouses

Axial flux motors represent a newer technology that offers high power density and efficiency in a compact form. They have a unique design where the magnetic flux is directed axially, allowing for shorter motor lengths. This makes them particularly suitable for EV applications where space is limited.

Switched Reluctance Motors: Simple Yet Effective

Switched Reluctance Motors (SRM) are known for their simplicity and robustness. They operate by switching the current to the stator windings to create a magnetic field that attracts the rotor. SRMs are attractive for EV use due to their potential for high efficiency and low production costs.

The diverse range of electric vehicle motors allows manufacturers to choose the best fit for their specific vehicle designs, balancing performance, efficiency, and cost. As technology advances, we can expect further innovations in motor design to enhance the capabilities of electric vehicles.

How to Evaluate EV Motor Performance

Assessing EV motor performance involves examining several critical factors that influence their operation and effectiveness. Electric vehicle motors are a crucial component of EVs, and their performance directly impacts the overall driving experience, efficiency, and range of the vehicle.

Measuring Power and Torque Output

The power and torque output of an EV motor are essential metrics that determine its ability to propel the vehicle. Power output is typically measured in kilowatts (kW), while torque is measured in Newton-meters (Nm). A higher power output enables faster acceleration, while higher torque provides better responsiveness.

Understanding Efficiency Ratings and Energy Consumption

Efficiency ratings are a critical factor in evaluating EV motor performance. Efficiency refers to the motor’s ability to convert electrical energy into mechanical energy. Higher efficiency ratings indicate lower energy consumption, resulting in longer ranges and reduced operating costs. EV motors with high efficiency ratings are typically more desirable.

Assessing Motor Cooling and Thermal Management

Motor cooling and thermal management are vital for maintaining optimal EV motor performance. Effective cooling systems help to prevent overheating, which can lead to reduced performance and lifespan. Common cooling methods include air cooling, liquid cooling, and hybrid cooling systems.

Analyzing Size-to-Performance Ratio

The size-to-performance ratio of an EV motor is another important factor to consider. A more compact motor with high performance capabilities is generally more desirable, as it allows for more flexible vehicle design and packaging. The table below compares the size-to-performance ratios of different EV motor types.

| Motor Type | Size (cm³) | Power Output (kW) | Size-to-Performance Ratio |

|---|---|---|---|

| DC Motor | 1200 | 50 | 0.042 |

| AC Motor | 1000 | 60 | 0.060 |

| Axial Flux Motor | 800 | 70 | 0.088 |

By examining these key factors, you can gain a comprehensive understanding of EV motor performance and make informed decisions when selecting or evaluating EV motors for various applications.

Practical Implications of Motor Choice in EVs

The selection of an electric vehicle (EV) motor significantly influences various aspects of the driving experience and overall vehicle performance. Different motor types can dramatically alter how an EV behaves on the road, its efficiency, and its maintenance requirements.

How Motor Types Affect Driving Experience

The driving experience in EVs is heavily influenced by the type of motor used. For instance, DC motors are known for their simplicity and provide a straightforward driving experience. However, they may lack the efficiency and performance offered by AC motors, which are more commonly used in modern EVs due to their ability to provide a smoother and more responsive driving experience.

Different motor types also affect the torque delivery and acceleration of EVs. For example, EVs equipped with axial flux motors can achieve higher power densities, resulting in better acceleration and a more responsive driving experience.

Motor Maintenance Requirements and Longevity

Maintenance requirements and longevity are critical factors to consider when evaluating EV motors. Brushless motors, such as those using AC technology, generally require less maintenance compared to their brushed counterparts, as they have fewer moving parts that can wear out.

- Regular checks on the motor’s electrical connections and cooling systems are essential.

- Software updates can significantly impact the motor’s performance and longevity.

- Understanding the manufacturer’s maintenance schedule is crucial for extending the motor’s lifespan.

Cost Considerations: Initial vs. Lifetime Value

When considering the cost of EV motors, it’s essential to look beyond the initial purchase price. While some motor types may be more expensive upfront, they can offer significant savings over the vehicle’s lifetime through improved efficiency and reduced maintenance needs.

For example, switched reluctance motors might have a higher initial cost but can provide long-term savings due to their simplicity and robustness.

Future Trends in EV Motor Technology

The future of EV motor technology is rapidly evolving, with several trends shaping the industry. Two significant advancements include solid-state motor controllers and integration with advanced battery systems.

Solid-State Motor Controllers

Solid-state motor controllers are expected to revolutionize EV technology by providing more efficient power management, reducing energy losses, and enhancing overall vehicle performance.

Integration with Advanced Battery Systems

The integration of EV motors with advanced battery systems is another critical trend. This integration can lead to optimized energy consumption, improved range, and enhanced driving dynamics.

As the EV market continues to grow, understanding these trends and their implications will be crucial for both manufacturers and consumers.

Electric Vehicle Motors: The Heart of Sustainable Transportation

Understanding electric vehicle motors is crucial for the widespread adoption of electric vehicles (EVs). As discussed throughout this guide, EV motor technologies play a vital role in determining the performance, efficiency, and overall driving experience of electric vehicles.

The various types of electric vehicle motors, including DC, AC, axial flux, and switched reluctance motors, each have their strengths and weaknesses. By evaluating factors such as power output, efficiency, and cooling systems, consumers can make informed decisions when choosing an electric vehicle.

As the demand for electric vehicles continues to grow, advancements in electric propulsion technologies will be essential for improving range, reducing costs, and enhancing the overall driving experience. By staying informed about the latest developments in EV motor technology, consumers can contribute to a more sustainable transportation future.